Problem:

Your plant needs maximized biological treatment while saving footprint…

…removing more nitrogen, TSS and phosphorus with less inputs. Your site needs a proven solution that works, whether it’s greenfield or retrofitting an SBR or conventional activated sludge (CAS).

Solution:

Cyclor® Turbo is SUEZ’ footprint-saving improvement on AGS…

…a fixed-level SBR with fast-settling densified sludge that nitrifies, denitrifies, biologically removes phosphorus, and even reduces solids. Here’s how:

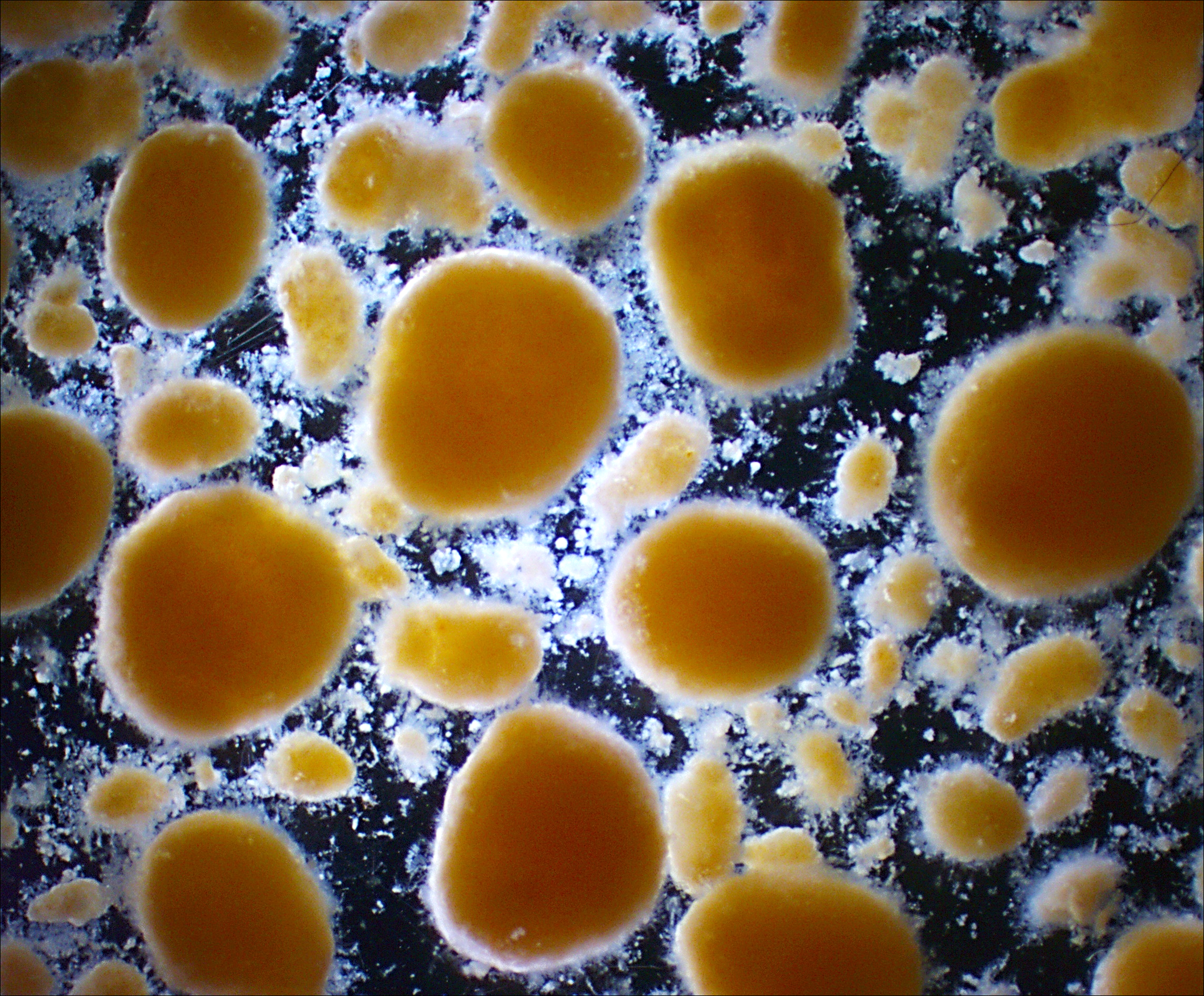

Microbiome is converted to densified biomass consortium with granular sludge for 4x higher settling velocity than the flocculated biomass in CAS. The partial granulation also captures more suspended solids in the settled sludge blanket than full granulation, enabling the reactor to produce <15 mg/L TSS.

Cyclor® Turbo’s densified biomass consortium with granular sludge.

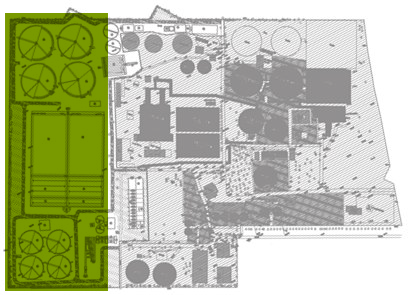

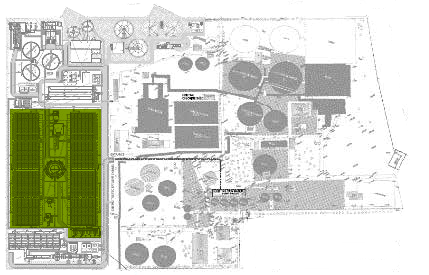

Requires up to 50% less footprint than CAS: Compresses the required treatment into a comparably small footprint, and the constant water level ensures that the head loss is also an improvement over CAS (and 3x less than conventional SBRs).

Above: Conventional activated sludge. Below: Using Cyclor® Turbo requires 50% less footprint on the same site.

At-a-glance

Key advantages:

- Up to 50% less footprint than CAS systems

- 4x sludge settling velocity than CAS systems

- Suitable for shallower basins than typical AGS

- Reduced OpEx through lower reagent use sludge production

Applications:

- Municipal wastewater

- Organic industrial waste

- Greenfield or retrofit projects

- Biological nutrient removal (TP & TN)

- SBR process intensification

Download Cyclor Turbo Cut Sheet

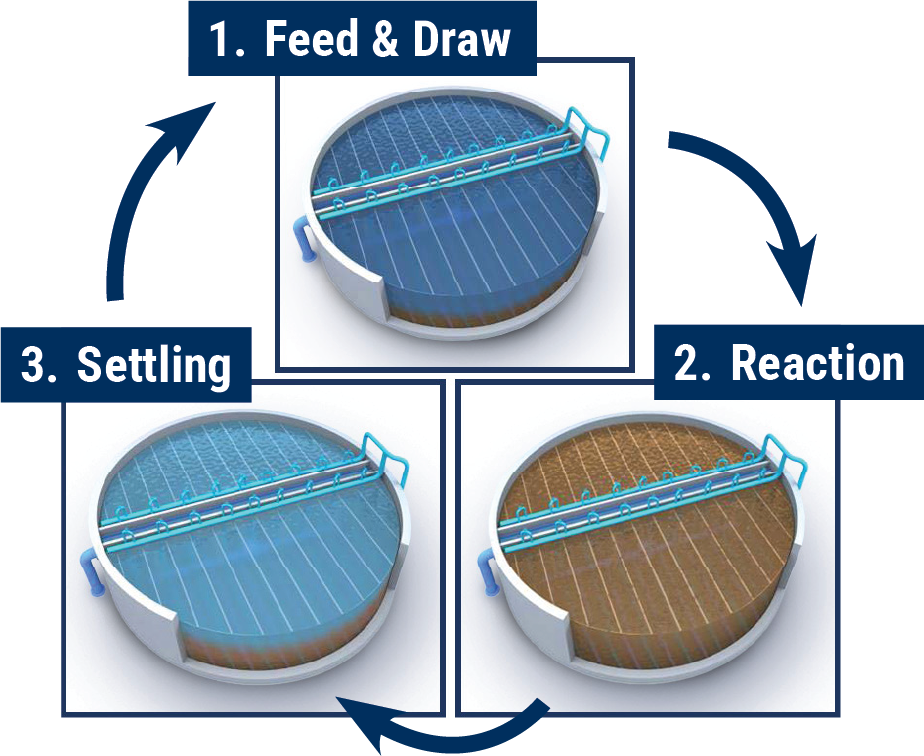

Flow within Cyclor® Turbo

Cyclor® Turbo’s water level remains constant through each step:

- Feed & Draw

While clean water is drawn off the reactor’s top, the reactor in its anaerobic state is fed from the bottom under the sludge blanket. This retains the heaviest sludge and naturally selects for phosphate accumulating organisms (PAO) that help further densify sludge. - Reaction

Aeration ensures mixing and oxygenation for BOD removal, nitrification, and phosphate consumption. The system is tuned to enhance denitrification and total nitrogen removal. - Settling

Aeration stops, allowing rapid sludge settling and denitrification to continue, producing a clear effluent.

Designed to be better

By reconfiguring an SBR based on a deep understanding how sludge works, Cyclor® Turbo achieves <10 mg/L TN, <15 mg/L TSS, and biologically removes phosphorus without reagent. It does this in half the footprint and with less O&M than conventional SBRs. Plus, Nexom—a name you trust—owns the quality of the delivered and finished product.

Proven Globally. Built for North America.

The 150 m³/day demonstration facility at a French coastal city was built and run for 18 months, with 100 variables analyzed every 10 seconds to conclusively define the process’ capabilities.

Installs:

- La Roche-sur-Yon (12.5 MGD, 47,400 m³/day)

- Libourne (2.9 MGD, 11,000 m³/day)

- Morainvillers (1.0 MGD, 3,900 m³/day)

- Central Manila (47.5 MGD, 180,000 m³/day)

In North America, Nexom is building a full-scale demonstration facility near its headquarters in cooperation with the East St. Paul, Manitoba wastewater treatment plant. Contact Nexom today to arrange a tour of the facility!

Want to know what Cyclor® Turbo could do for your system?

Submit your RFP today and our in-house professional engineering team can help you size and design a system to meet your wastewater treatment requirements.

How much does a Cyclor® Turbo system cost?

There are many factors which can influence the cost of a Cyclor® Turbo system, including design flows, loading, treatment requirements, and existing infrastructure. The best way to determine the cost for your specific application is to submit your RFP to our project development team.

What type of wastewater can Cyclor® Turbo treat?

Cyclor® Turbo can treat a variety of wastewater streams. The general requirements are that the wastewater should not be toxic and must contain sufficient organic carbon to at least partially sustain biological nitrogen and phosphorus removal.

Can Cyclor® Turbo be retrofitted into existing CAS or SBR systems?

Yes, Cyclor® Turbo can be easily retrofitted into existing tanks, regardless of their shape. One of the main considerations is tank depth. Depending on the flows and loads of a particular plant, Cyclor® Turbo can operate in tanks as shallow as 4.5 meters. Retrofitting Cyclor® Turbo into an existing system is an effective way to significantly expand plant capacity without altering the plant’s footprint.

How is Cyclor® Turbo’s granule formation initiated and maintained?

-

- Selective sludge wasting: This involves removing light, slowly settling flocs while retaining granules and dense, heavy flocs.

- Alternating feast and famine conditions: Raw wastewater is fed into the sludge bed through a homogeneous network at the bottom of the tank under anaerobic conditions, followed by an aerated reaction phase. This promotes the growth of microorganisms that form dense aggregates, such as phosphorus-accumulating organisms (PAOs).

The system can be started up using seed sludge from any CAS plant—there is no need to import specialty sludge for process startup.

Have a question that wasn’t answered here?

Ready to Upgrade?

Nexom makes upgrading easy:

- We walk you through the project details.

- We supply design-ready drawings and responsive support.

- You never worry about nutrient limits or footprint constraints again.