Glencoe, Ontario

Upgrading for post-lagoon nitrification, without abandoning existing infrastructure.optAER® SAGR®

Project Information

Location: Glencoe, Ontario

Project Type: Municipal Wastewater Treatment

Completion Date: March 2011

Treatment Objectives

Design flow: 1742 m3/day (0.46 MGD)

TAN: <1.0 mg/L

BOD: <7.0 mg/L

TSS: <7.0 mg/L

TP: <0.3 mg/L[/et_pb_text][et_pb_text _builder_version="4.16" _module_preset="default" custom_margin="||1px|||" global_colors_info="{}" theme_builder_area="post_content"]

Other case studies you may be interested in:

Shellbrook, SK

Shellbrook’s objective was to treat its wastewater to the standards set by the CCME (Canadian Council of Ministers of the Environment), which Saskatchewan Environment was in the process of adopting.

Pilot Butte, SK

Back in 2014, Pilot Butte’s population had just climbed past 2,500, and with several developments in progress, the Saskatchewan municipality needed to upgrade their two-cell facultative lagoon system to allow for more treatment capacity.

Park View, Iowa

Sanitary district upgrades lagoons for full cold weather ammonia nitrification within existing footprint.

Absarokee, MT

Fully utilizing a combination of Nexom’s expert technologies for BOD reduction and cold-water nitrification

Project Background & Challenges

You’ll find the City of Glencoe approximately 250 km southwest of Toronto, Ontario. A small community of approximately 6,000 residents, Glencoe is a national winner for the Communities in Bloom program and home to Mosa Forest, a 3600-hectare area of old-growth hardwood forest and wetland plants significant for its diversity of rare and at-risk animal and plant inhabitants.

Approximately 500 hectares can be found near Glencoe, in the County of Southwest Middlesex, where it is known locally by the name Skunk’s Misery. As one of the largest and most significant forested blocks remaining in southern Ontario, the area is a designated Carolinian Canada site, a Provincially Significant Wetland, an Area of Natural and Scientific Interest and a Nationally Important Bird Area. Its ecological significance also means it is protected from development for natural and scientific purposes.

The wastewater treatment facility serving Glencoe and the Municipality of Southwest Middlesex was first constructed in 1975 and consisted of two facultative wastewater treatment lagoons discharging into Newbiggen Creek. The lagoons were initially designed for seasonal discharge in early spring and late fall. But by 2005, the facility was operating at maximum hydraulic loading and a new solution needed to be found.

A common solution for increasing capacity, without constructing additional lagoons, is to convert the process from seasonal to continuous discharge. However, the proximity to Skunk’s Misery placed significant importance on creating a solution that would have minimal environmental impact, while also meeting the effluent quality permit requirements on a year-round basis.

The Nexom Answer

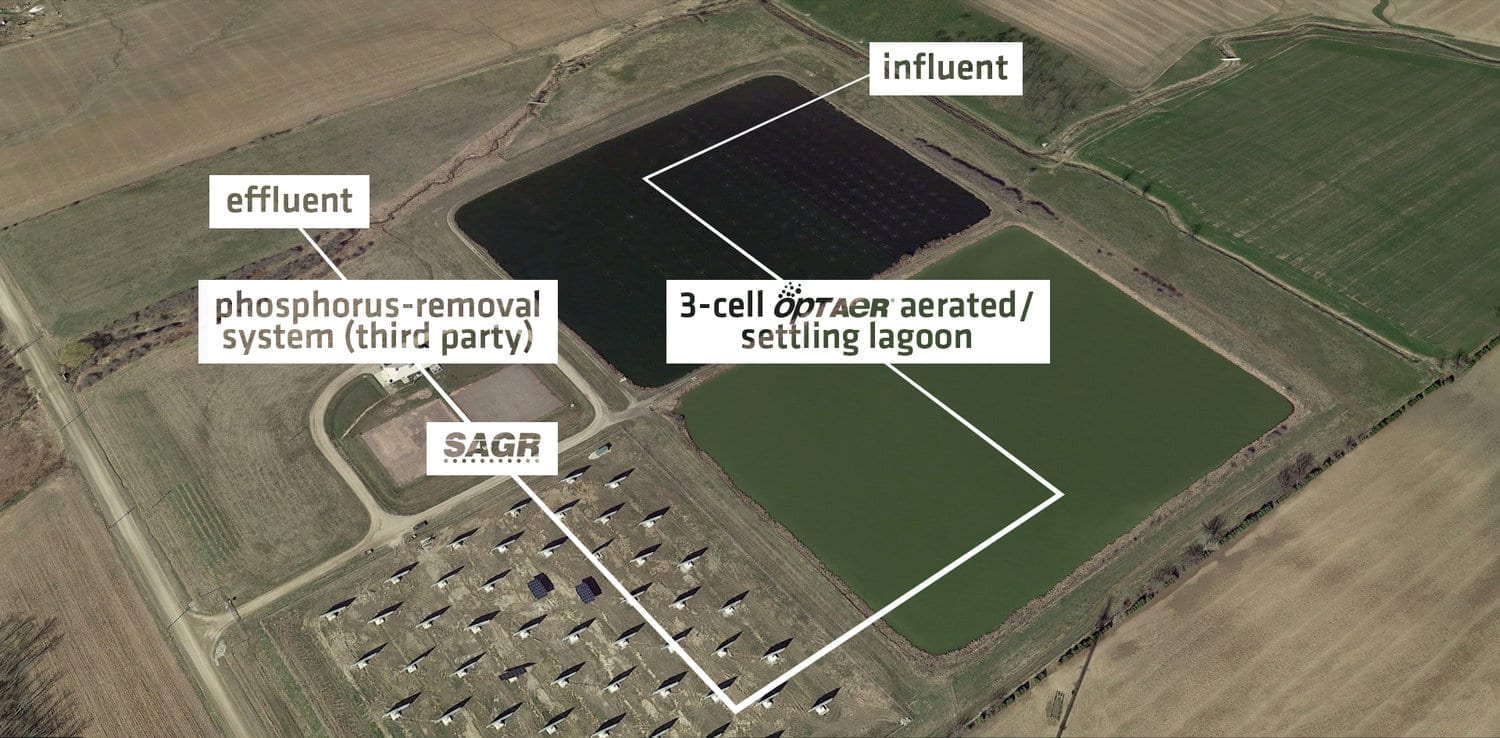

Glencoe, Ontario’s treatment facility process flow.

A common option for increasing capacity, without constructing additional lagoons, is to convert the process from seasonal to continuous discharge. However, this change would also require the effluent quality meet permit requirements on a year-round basis.

Federal Wastewater Systems Effluent Regulations (WSER) require that the effluent from any Canadian municipal WWTF can not exceed 1.25 mg/L of un-ionized ammonia. However, research conducted by Saskatchewan’s Water Security Agency suggests that effluent un-ionized ammonia, a component of Total Ammonia-Nitrogen (TAN) which is positively correlated with pH and temperature, needs to be as low as 0.2 mg/L to ensure non-toxicity to fish.

Working with engineers from The Thompson Rosemount Group (TRG) Inc, Nexom proposed upgrading the existing lagoons using the Nexom optAER® system, followed by a SAGR® for nitrification. These changes would enable the WWTF to meet its nitrification limits year-round.

Installation of optAER fine bubble aeration in the existing lagoons:

The optAER lagoon-based wastewater treatment system is used in a broad spectrum of applications. In comparison to a mechanical treatment facility, optAER process-enhanced sites can be implemented at a fraction of the cost but still maintain the simplicity of a lagoon system. Aeration also provides internal sludge digestion, resulting in minimal long-term solids accumulation, and extending the life of ponds and lagoons.

Of the existing facultative treatment lagoons, only one was kept in operation. The eastern lagoon was taken offline, to be used as a storage facility when needed, in the case of maintenance or bypass of the western treatment cell.

Meanwhile, the western cell was divided into three partial mix aerated cells, which would be operated in series using geomembrane floating baffle curtains. The curtains were used to divert flow and help the WTTF achieve improved year-round BOD and TSS removal through bacterial degradation and solids settling. With aerated partial mix cells, the diffuser density is based upon oxygen demand. The optAER system does not rely on algae or natural surface aeration to provide oxygen to the wastewater.

Aeration aids in the primary treatment of contaminated water in the form of oxygen, as well as residence and contact time for the natural bacteria who ultimately convert wastewater contaminates into carbon dioxide, water, and inert ash. The focal point of the optAER system is the fine-bubble aeration provided by diffusers, which are tied to floating laterals floating on the water’s surface and suspended near the bottom of the pond. If the bottom of the lagoon is uneven, the marine grade suspension rope can be used to suspend the diffusers from the header to allow for uniform diffuser elevations. This location provides protection from ice movement and maximizes the oxygen transfer efficiency of the system.

Laterals are secured against wind action with a stainless-steel cable system. The cables are fastened to anchors in the lagoon berm using a self-adjusting lateral tensioning assembly. All header and lateral piping, joints, and fittings are thermally fused HDPE. With floating laterals, the cells do not have to be dewatered or taken out of service for system installation or maintenance. All maintenance can be performed from a boat with a 2-person crew.

Implementation of a horizontal flow aerated SAGR:

Lagoon-based treatment systems provide some nitrification (ammonia removal) during the summer months but are generally incapable of meeting low ammonia limits during prolonged periods of low water temperatures.

The SAGR system was developed in Canada to address this issue. Lagoons are incredibly powerful ecosystems that can cost-effectively and naturally remove a host of wastewater’s most harmful components with a minimum of operations or maintenance requirements. But lagoons often struggle to remove ammonia in winter, due to:

- Cold winter water temperatures that slow bacterial metabolism and reproduction;

- Lack of oxygen needed by nitrifying bacteria, particularly if lagoons freeze over;

- Too much competition from BOD-consuming heterotrophic bacteria;

- Lack of available surface area for the nitrifying bacteria to grow on.

The SAGR is a patented process providing full nitrification, as well as BOD and TSS polishing, in cold to moderate climates. The SAGR is essentially a clean aggregate media bed designed with even wastewater distribution and collection. Linear aeration throughout the floor of the SAGR provides aerobic conditions required for ammonia removal.

At Glencoe, the treatment facility consists of two aerated beds in tandem. Design objectives were set at 50% of compliance limit approved by the Ontario Ministry of Environment (MOE). With a design flow capacity of 1742 m3/day, the upgraded system has nearly twice the maximum hydraulic capacity of the previous design. The capacity increase will meet future demands based on a 30-year design life.

Site Construction

Upgraded System PerformancE

The wastewater treatment facility at Glencoe was commissioned in March 2011. Blower tests, adjustments and setup were completed on March 21-22nd, with operator training taking place on March 23rd.

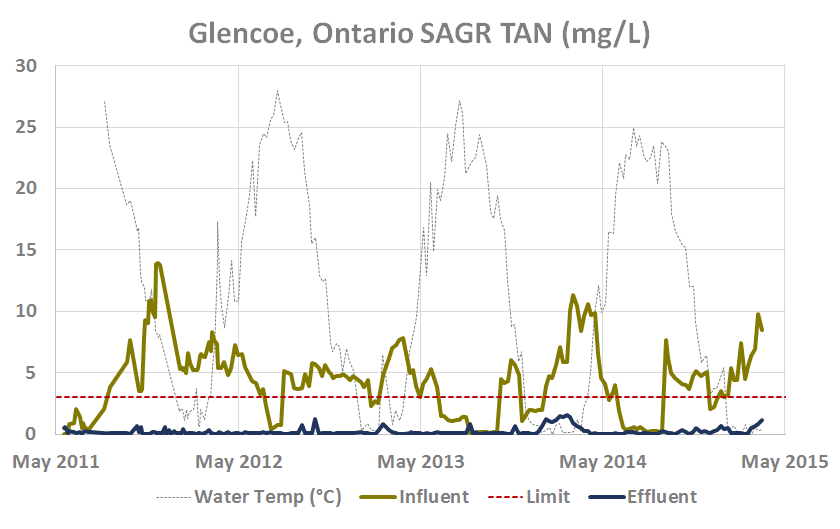

Following these upgrades, Glencoe’s wastewater treatment facility has consistently met ammonia effluent limits of < 3.0 mg/L, as well as the effluent objectives of < 1.0 mg/L when water temperatures drop as low as 32.9°F / 0.5°C.

In addition to increased capacity and improved effluent quality, the overall footprint of the facility was decreased by approximately half, allowing for future expansion without a footprint increase. This added capacity also created room for surrounding communities to tie into the system, including the hamlets of Appin and Melbourne. The components and design approach demonstrate the ability to increase hydraulic capacity and provide nutrient removal in a lagoon-based process, while maximizing the se of existing lagoon infrastructure and maintaining low operation.

Due to the ongoing and rapid expansion of the community, it was decided rather than continuing to treat the water themselves, that the wastewater would instead be transferred to the nearby City of Sasktoon for treatment.

Planning began in 2019. Under this proposal, the existing lagoons in Martensville would now become equalization basins for the pumping system. Equalization basins are used to provide consistent influent flow to downstream wastewater treatment processes by retaining high flow fluctuations. The purpose of flow equalization is to balance out the process parameters, such as flow rate, organic loading, strength of wastewater streams, pH, and temperature over a 24-hour period.

Due to the additional retention time, aeration and mixing would still be required to prevent raw wastewater from becoming septic and to maintain solids in suspension. This will mean fluctuating water levels, which can be problematic for floating aeration systems. However, since Martensville has a Float-Sink aeration system, which allows for the laterals to be raised or lowered easily when required, this challenge could be easily overcome. Under this new plan, Martensville will continue to use the Float-Sink lateral aeration equipment as part of the design of the new facility, when the ponds are converted into equalization basins.