PALMYRA, WI

Retrofitting the existing lagoon for maintaining simple and reliable treatment to new specific limits.BioPorts™

Project Background & Challenges

Since the late 1970s, the Village of Palmyra, WI Wisconsin was operating a three-stage aerated lagoon. Faced with requirements for additional capacity and more stringent effluent limits, including a new winter effluent ammonia limit, the Village of Palmyra began looking at options to upgrade their existing infrastructure.

The Nexom Answer

MSA Professional Services solicited the help of Nexom to look at options for upgrading Palmyra’s existing lagoons. Together, MSA and Nexom developed a retrofit solution that utilized the existing infrastructure while maintaining simple and reliable treatment to meet the new limits. To upgrade the lagoons, Nexom provided optAER® lagoon aeration for the existing primary pond and insulated lagoon covers for both the existing primary and final polishing ponds. Nexom also provided a BioPorts Moving Bed Biofilm Reactor (MBBR) for cBOD₅ polishing and nitrification following the aerated and covered primary pond. The MBBR is followed by a small coagulation/flocculation reactor mixed by Nexom’s CoarsAir Max diffusers. Coagulation/flocculation enhances the settleability of MBBR effluent solids, as well as precipitates phosphorus, prior to settling in the covered polishing pond. Overall, the system is designed to obtain <25 mg/L cBOD₅, <25 mg/L TSS, and <5 mg/L NH₃-N.

Meeting <5 mg/L Total Ammonia Nitrogen at 4°C with Minimal O&M Requirements

At the core of the wastewater treatment upgrades is Nexom’s BioPorts MBBR. BioPorts utilizes patented carrier material to cultivate a specialized treatment biomass capable of removing cBOD₅ and ammonia even at temperatures as low as 4°C. The process is simple to operate because the carriers are physically retained in the reactor with stainless steel retention screens. Therefore, operators do not need to worry about balancing waste and return sludge streams – the biofilm is self-maintaining and automatically adjusts to treat influent cBOD₅ and ammonia loads. The process only requires dissolved oxygen, which is provided by blowers via Nexom’s course bubble diffusers mounted to the bottom of the MBBR. Microorganisms in the biofilm utilize the dissolved oxygen to convert cBOD₅ and ammonia to carbon dioxide and nitrates, thereby eliminating effluent toxicity.

Upgraded System Performance

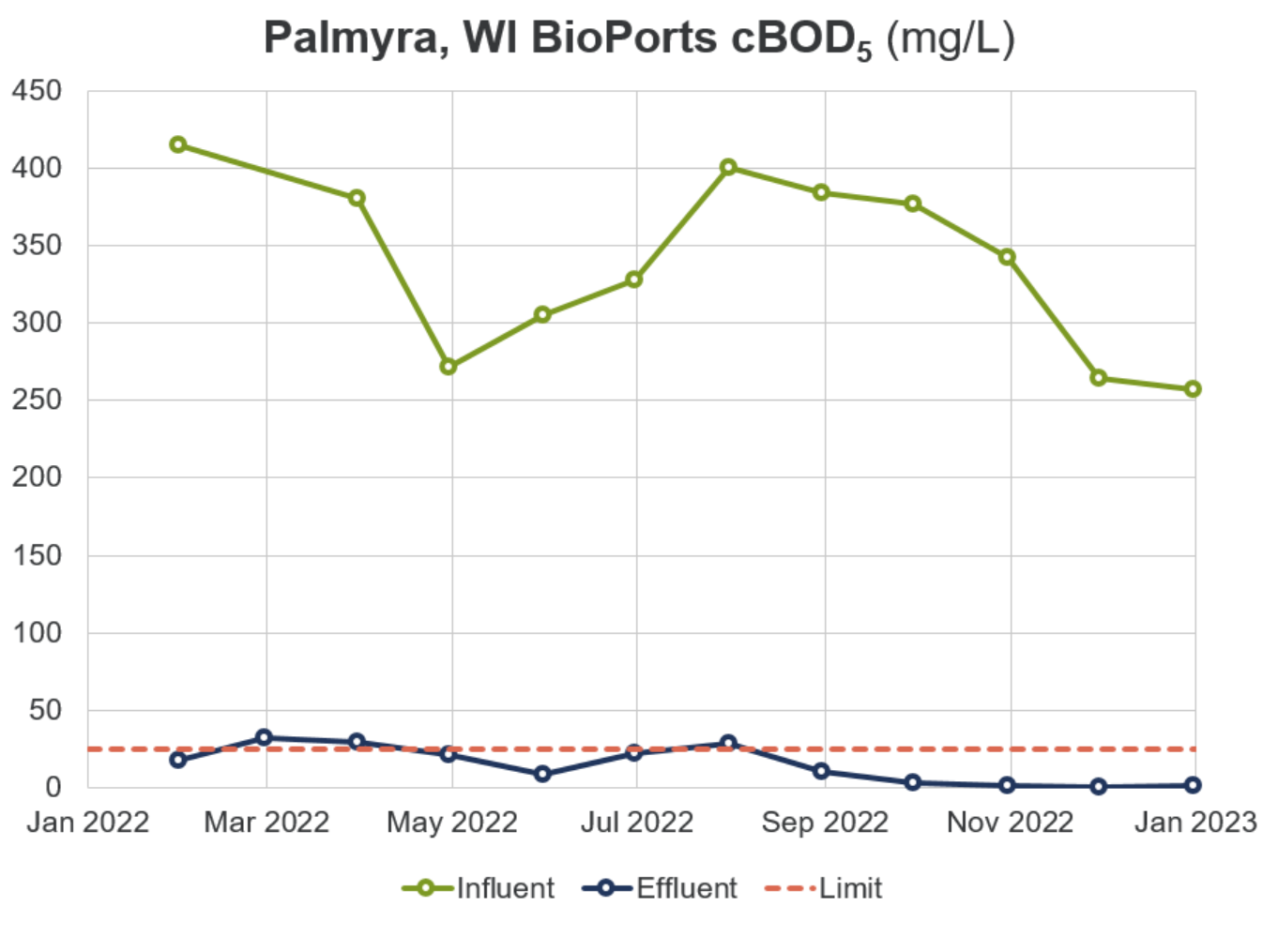

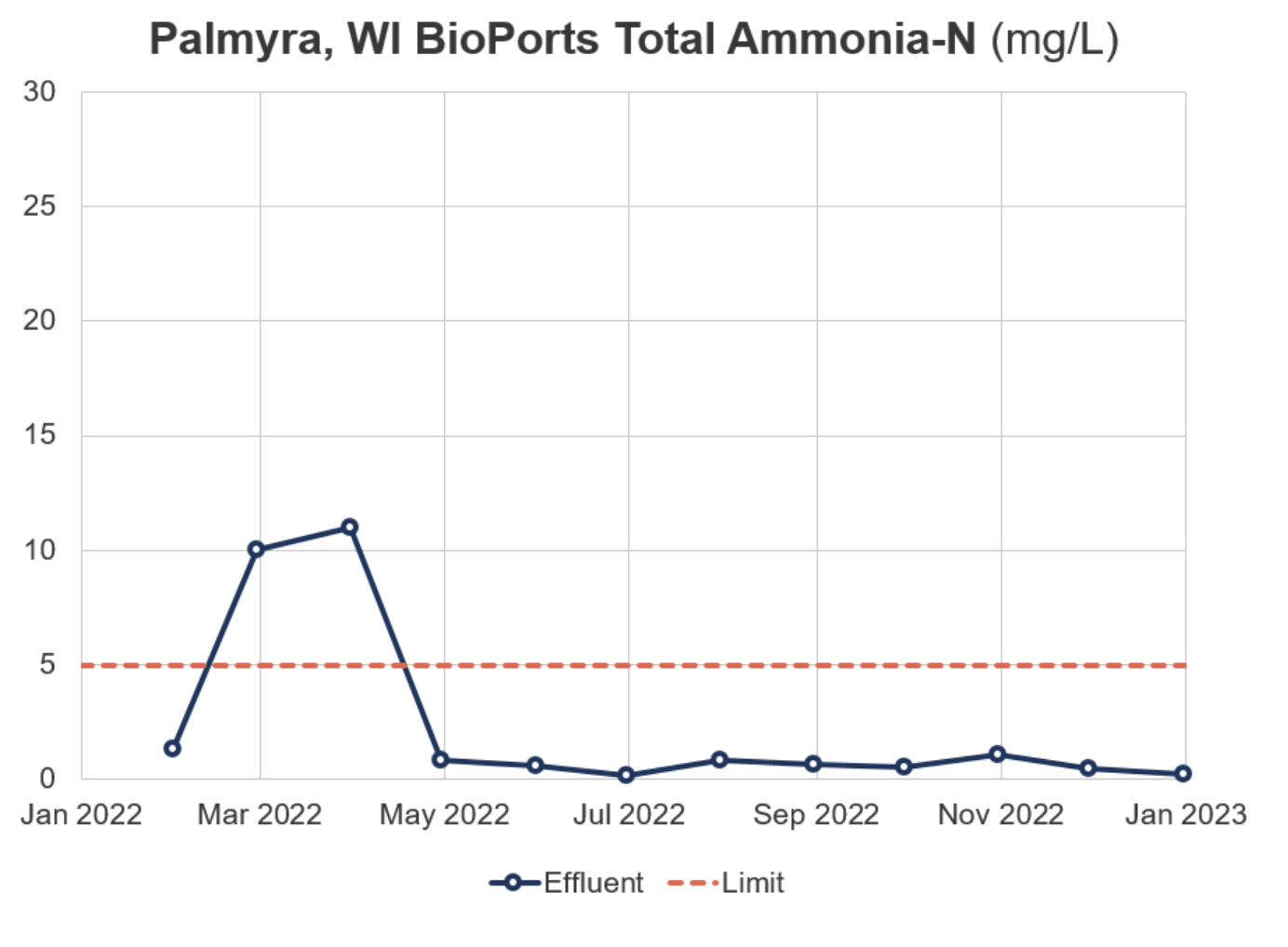

The system has been providing wastewater treatment for Palmyra since being commissioned in January 2022. Effluent samples from March 2022 indicated that the system had fully acclimated, with NH3-N concentrations <0.5 mg/L towards the end of winter. The following graphs show the successful performance of Palmyra’s MBBR from March through the end of 2022.

Project Information

Project Type: Municipal wastewater treatment

Completion Date: January 2022

Treatment Objectives

Design flow:

- 23 MGD

- Max Month: 0.39 MGD

- Peak Hour: 600 GPM

Effluent quality:

- <5 mg/L NH₃N

- <25 mg/L cBOD₅

- <25 mg/L TSS

You may also be interested in:

Wabaseemoong Independent Nations

Wabaseemoong Independent First Nations are a group of three communities located near the Ontario–Manitoba border about 120 kilometers north…

Maricopa, Arizona

In 2019, the Global Water – Palo Verde Water Reclamation Facility (WRF), located in northeastern Maricopa, AZ, was serving a growing population of 48,629 residents, while also seeing adjustments to their permit in their future.

Absarokee, MT

Fully utilizing a combination of Nexom’s expert technologies for BOD reduction and cold-water nitrification